Technical facts & support

Please feel free to contact our customer service if your have any further questions.

The key factors in maintaining the blade’s condition include:

a. Environment: Store the blade in a cool, dry place to prevent rust and corrosion. Avoid areas with high humidity or extreme temperatures.

b. Packaging: Keep the blade in its original packaging or wrap it in a protective material like rust-inhibiting paper.

c. Position: Store the blade flat or on a proper rack to prevent bending or warping. Avoid placing heavy objects on top of it.

d. Check Regularly: Periodically inspect the blade for any signs of rust or damage.

If you follow these guidelines, a band saw blade can remain in good condition for several years. However, it’s always a good idea to inspect it for any issues before using it, especially if it has been stored for a long time.

1. Material Type

Different materials require specific blade types and configurations. For example, bimetal blades are suitable for a variety of metals, while carbide or diamond-studded blades are better for very hard materials.

2. Cutting Speed and Feed Rate

Adjust the speed and feed rate according to the material being cut. A too high speed or feed rate can cause excessive wear and reduce the blade’s lifespan, while a too low rate can lead to inefficient cutting.

3. Blade Tension

Proper blade tension is crucial for accurate cutting and preventing blade breakage. Check and adjust the tension according to the manufacturer’s recommendations.

4. Coolant Usage

Use appropriate coolant to reduce heat and friction during cutting, which helps in extending blade life and improving cut quality. Ensure the coolant is suitable for the material and blade type.

5. Blade Teeth and Gullet Size

Choose a blade with the appropriate tooth pitch and gullet size for the material being cut. This helps in efficient chip removal and prevents clogging.

6. Cutting Angles

Properly align the blade and material to maintain straight cuts and reduce unnecessary wear.

7. Blade Cleaning and Maintenance

Regularly clean the blade to remove debris and resin buildup. Inspect the blade for signs of wear, damage or dull teeth and replace or sharpen it as needed.

8. Workpiece Support

Ensure proper support for the workpiece to avoid vibrations and movement during cutting, which can affect blade performance and accuracy.

9. Safety Precautions

Follow the safety guidelines, including wearing appropriate personal protective equipment (PPE) and ensuring that the machine is properly maintained and set up.

By carefully managing these factors, you can maximize the performance and longevity of your metal band saw blade.

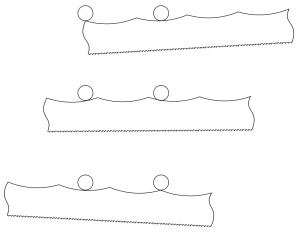

WAVE TECH TECHNOLOGY

WAVE TECH: Sawing with in-curve back profile.

A special-designed back profile forces bandsaws to deflect during running, which tremendously improves tooth penetration.

The patented processing to treat the back ensures back edge’s excellent surface finish.

WAVE TECH Features

a. Various customization options according to the size of the sawing machine and the size of the workpiece material to be cut.

b. No changes in speed & feed rate.

c. Increase of efficiency up to 30-50% and blade life up to 50% without change of machine parameters.

d. Excellent suitability for solid materials.

e. Free product use assistance.

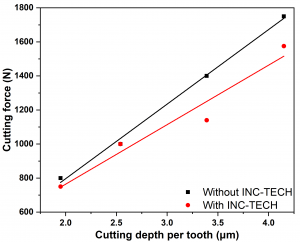

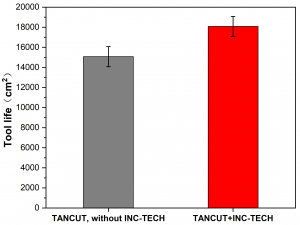

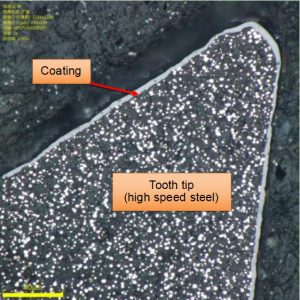

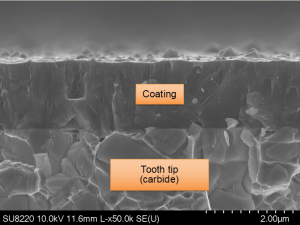

SHD TECHNOLOGY-COATING

SHD stands for a hard coating like SHIELD (SHD) to protect the teeth.

The development of advanced processing technology (high-speed and high-efficient machining) and the wide usage of difficult-to-cut materials (such as hardened steels or nickel and titanium based aviation materials) can lead to rapid wear failures for both bi-metal and carbide bandsaw blades. The use of advanced coated tools prepared through physical vapor deposition (PVD) has been proved to be critical to minimize potential losses.

Facing the various machining conditions of different processed materials, the Bichamp SHD TECHNOLOGY can provide advanced coating solutions based on our customers’ demands. Just like a shield can protect a person, SHD-treated band saw blades benefit from:

a. Advanced manufacturing accuracy of the bandsaw

b. Increased surface hardness of the cutting tooth

c. Superior adhesion between the coating and the bandsaw

d. High toughness for uninterrupted cutting

e. Reduced friction coefficient and heat of cutting

f. Limited formation of built-up-edge

g. The possibility of dry cutting

h. Extraordinary surface quality of the cross section

i. Big improvements in productivity

j. Great reductions in manufacturing organization costs

The Bichamp SHD coated bandsaw series consist of both bi-metal and carbide blades, the cutting parameters vary depending on the applications. If you are searching for a solution for the difficult-to-cut materials machining or the cost containment, then you are welcome to contact our sales representatives or technical support for assistance.

|

|

|

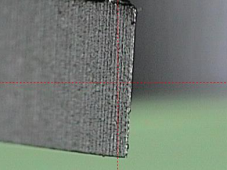

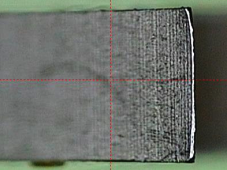

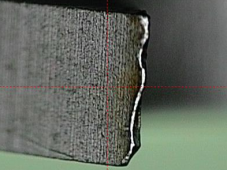

| Before break-in | After proper break-in | After improper break-in |

| Tooth tips are very sharp and

may contain small burs from manufacturing. |

Proper break-in makes the blades gain a

good tooth tip with a small round cutting edge, which is beneficial for a prolonged blade life. |

Improper break-in results in

disastrous chipping on tooth tips, which may significantly shorten the blade life. |

For bi-metal bandsaw blades:

1) Use the recommended band speed for the material you want to cut.

2) Reduce the feed rate by 30-40%

3) Run the blade for 30-60 min and slightly increase the feed with every cut.

4) Set band speed and feed rate as normal.

For carbide bandsaw blades:

1) For the first cut, set feed and band speed parameters as for a Bimetal.

2) For the second cut, increase band speed while avoiding vibration.

3) Then increase feed to match band speed while avoiding vibration.

4) Repeat second cut till you have reached normal parameter settings for a Carbide Blade.

Speed Chart

For bimetal band saw blades

| Steel grade | Dimension ф (mm) | 100 | 200 | 300 | 400 | 500 | 700 | 1000 |

|---|---|---|---|---|---|---|---|---|

| Carbon steel/Low alloy steel | Band speed (m/min) | 50-85 | 50-75 | 45-65 | 40-50 | 35-45 | 30-40 | 25-35 |

| Efficiency (cm2/min) | 45-70 | 50-80 | 45-65 | 35-50 | 35-45 | 25-35 | 20-30 | |

| Cr alloy steel/Cr-Mo steel/Ni-Cr-Mo steel | Band speed (m/min) | 50-65 | 50-60 | 45-55 | 40-50 | 35-45 | 30-40 | 20-30 |

| Efficiency (cm2/min) | 30-50 | 40-48 | 35-42 | 30-40 | 28-36 | 22-32 | 16-25 | |

| Mold steel/Hot-work steel/Cold-work steel/Tool steel | Band speed (m/min) | 24-40 | 24-40 | 22-40 | 20-35 | 20-35 | 18-30 | 16-25 |

| Efficiency (cm2/min) | 8-20 | 16-30 | 14-30 | 12-28 | 12-28 | 10-25 | 8-18 | |

| Stainless steel | Band speed (m/min) | 40-50 | 35-45 | 35-40 | 28-35 | 25-32 | 20-28 | 18-25 |

| Efficiency (cm2/min) | 20-30 | 28-35 | 26-32 | 20-30 | 18-25 | 15-22 | 10-18 |

· The chart is only for materials with a hardness of 20HRc or 225HB. When the hardness is ~30HRc or 283HB, slow the speed to 70% of the recommended value in the chart.

· When the hardness is ~35HRc or 330HB, slow the speed to 60% of the recommended value in the chart. Bimetal is not suggested for workpieces with a hardness higher than 40HRc.

· Actually, bandsawing parameters are strongly affected by external factors like machine condition, materials, fluid, etc. So your experience is very important.

For Carbide Band Saw Blade

| Steel grade | Dimension Ф (mm) | 100 | 200 | 300 | 400 | 500 | 700 | 1000 |

|---|---|---|---|---|---|---|---|---|

| Hard wood | Band speed (m/min) | 1200-1500 | 1200-1500 | 1200-1500 | 1200-1500 | 1200-1500 | ||

| Efficiency (cm2/min) | 6500-7200 | 1800-2000 | 1800-2000 | 1500-1600 | 1500-1600 | |||

| Aluminum alloy | Band speed (m/min) | 1200-1500 | 1500-2000 | 1500-2000 | 2000-2500 | 2000-2500 | 2000-2500 | 2000-2500 |

| Efficiency (cm2/min) | 1000-1200 | 1000-1200 | 1000-1200 | 1400-1800 | 1400-1800 | 1400-1800 | 1400-1800 | |

| Stainless steel | Band speed (m/min) | 25-30 | 25-30 | 25-30 | 25-30 | 25-30 | 25-30 | |

| Efficiency (cm2/min) | 5.0-6.0 | 5.0-6.0 | 5.0-6.0 | 4.5-5.5 | 4.5-5.5 | 4.5-5.5 | ||

| Case-hardened steel | Band speed (m/min) | 40-50 | 40-50 | 35-45 | 35-45 | 35-45 | ||

| Efficiency (cm2/min) | 10-15 | 10-15 | 10-15 | 10-15 | 10-15 | |||

| Titanium alloy | Band speed (m/min) | 30~45 | 30~45 | 30~40 | 30~40 | 25-35 | 25-30 | 20~25 |

| Efficiency (cm2/min) | 14-18 | 14-18 | 14-18 | 12-16 | 12-16 | 10-14 | 10-14 | |

| Superalloy | Band speed (m/min) | 25-30 | 25-30 | 20-25 | 20-25 | 20-25 | 20-25 | |

| Efficiency (cm2/min) | 3.5-8 | 3.5-8 | 3.5-7 | 3.5-7 | 3.5-6 | 3.5-6 |

Depending on the workpiece, the band saw and the parameters of your machine, problems may occur during operation.

We have provided a comprehensive list of possible failures including their causes and possible solutions in our operation tips section.