Guidebook for Bimetal

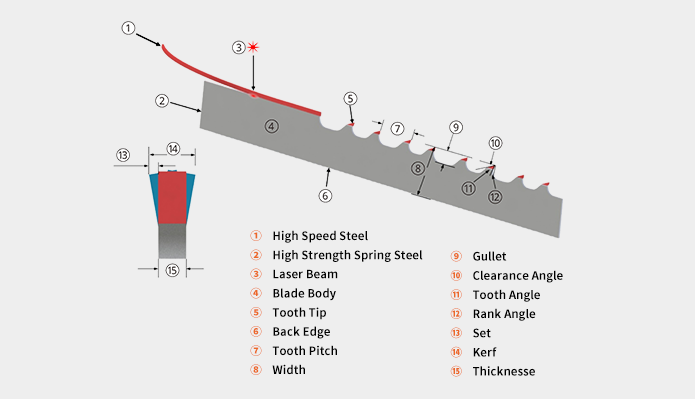

TERMINOLOGY

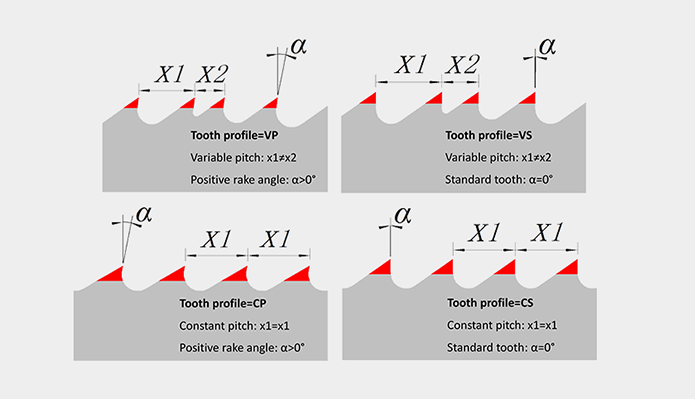

TOOTH PROFILE

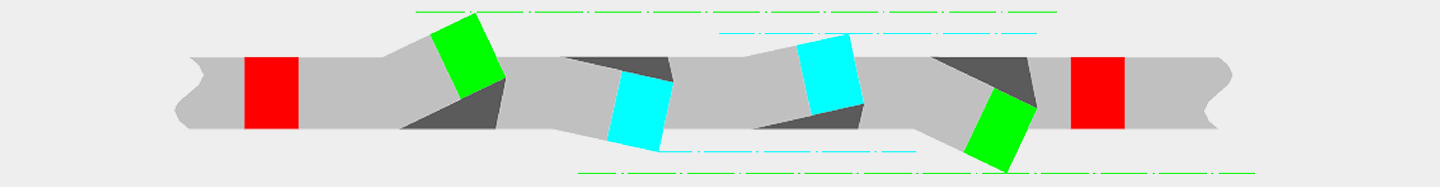

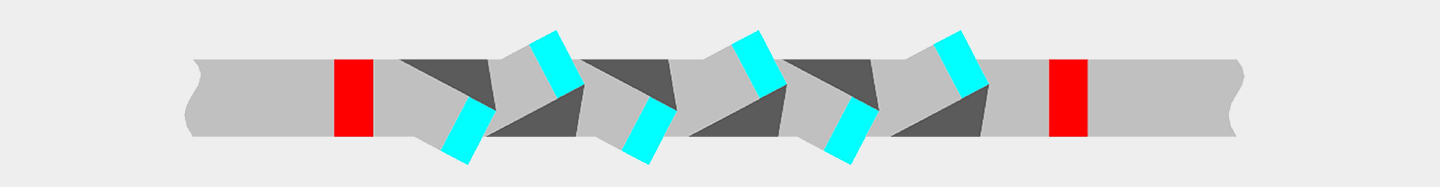

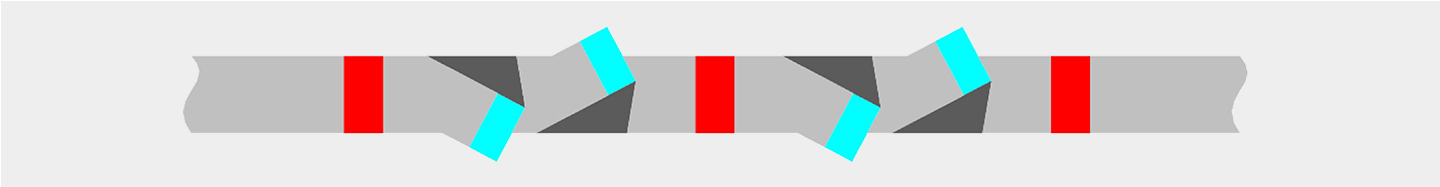

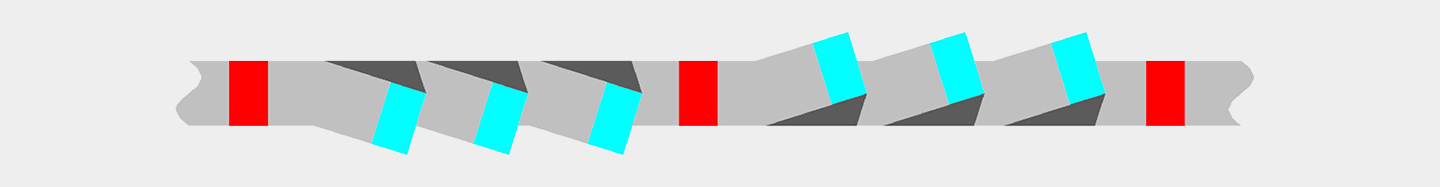

SETTING

GROUP SET(G)

For variable pitch of FI CUT, AA CUT, AA CUT M51, PRO CUT except for 14/18 TPI

STANDARD SET(S)

For constant pitch except for 19 x 0.9-18 TPI

WAVY SET(W)

For 14/18 TPl and 19 x 0.9-18 TPI

VARIABLE SET(V)

For AA CUT PLUS M42 and PRO CUT